Alya

About Us

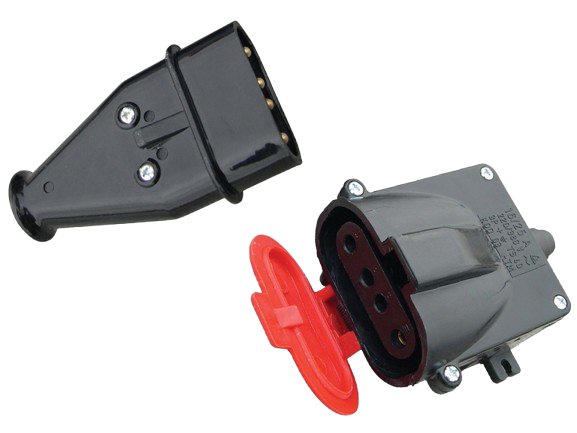

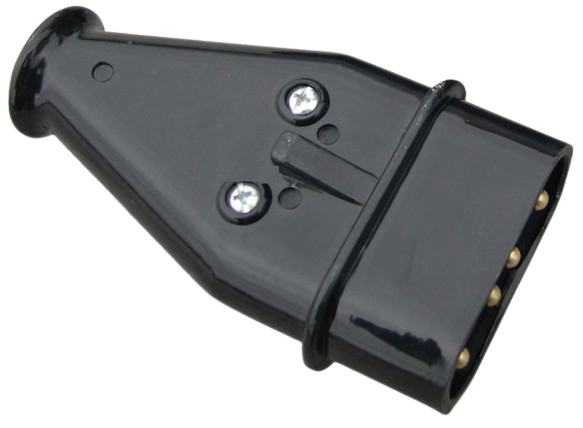

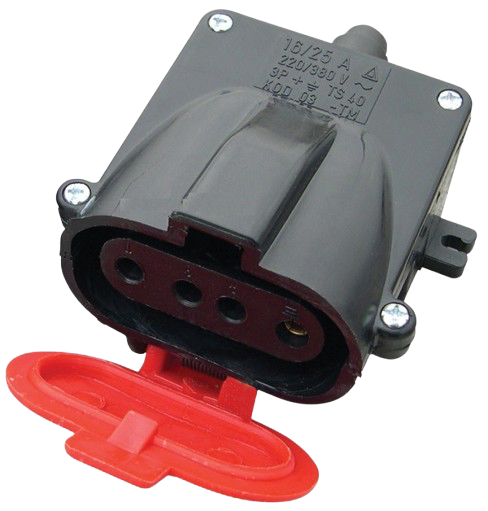

Industrial Plastics and Electrical Materials

Specializing in the production of industrial plastics and electrical materials, ALYA has been providing reliable, durable, and high-performance solutions to the needs of industrial manufacturing since 2014. Combining the strength of domestic production with modern technology, our company aims for sustainable excellence in both product quality and service processes.

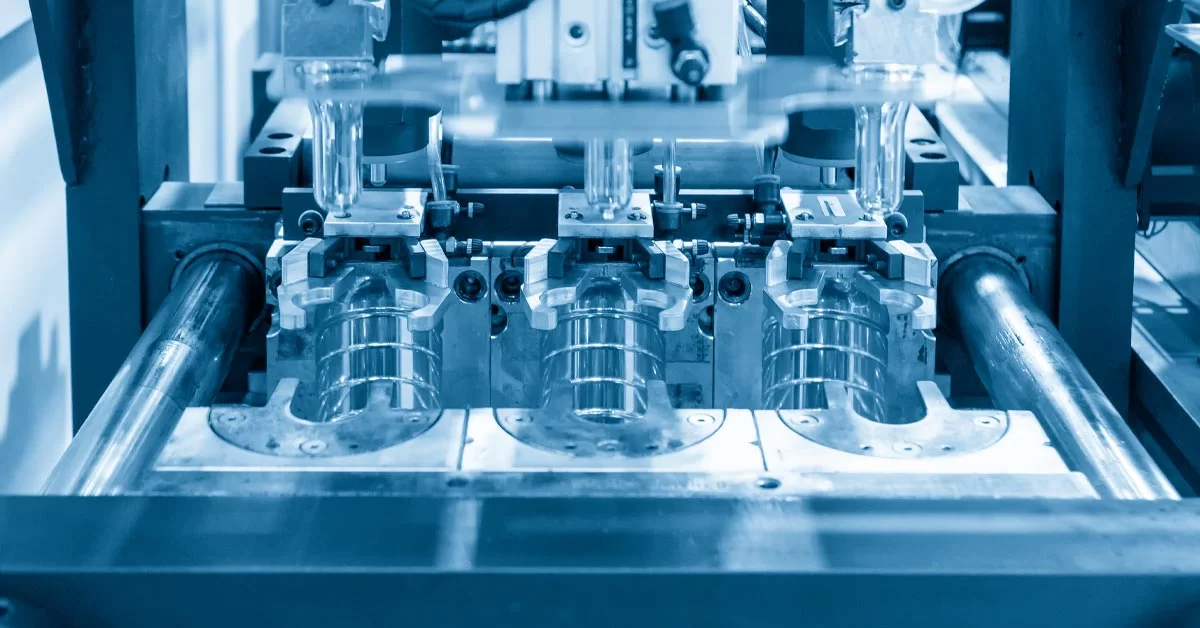

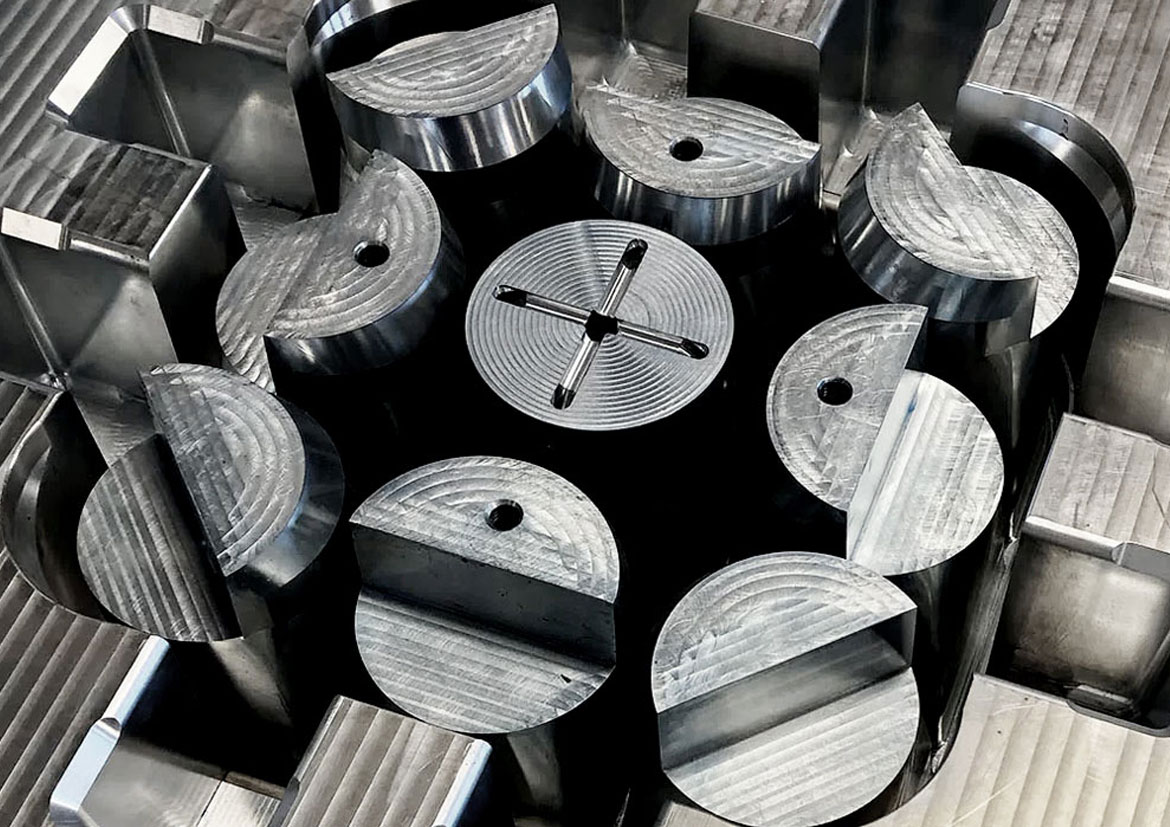

Thanks to the injection molding machines, machining systems, and mold production equipment in our manufacturing facility, we efficiently perform contract injection molding, metal processing, plastic mold production, and mold maintenance & revision services.

With our flexible structure that offers tailored solutions for our customers' projects, we are able to serve a wide range—from small series production to large-scale industrial projects. Through our technical expertise and well-equipped infrastructure, quality control procedures are meticulously applied at every stage, ensuring on-time and seamless delivery to the customer.

Adopting the principle of 'trust, speed, and quality' in every stage of production, ALYA operates not just as a product supplier, but as a manufacturer that acts as a true solution partner.