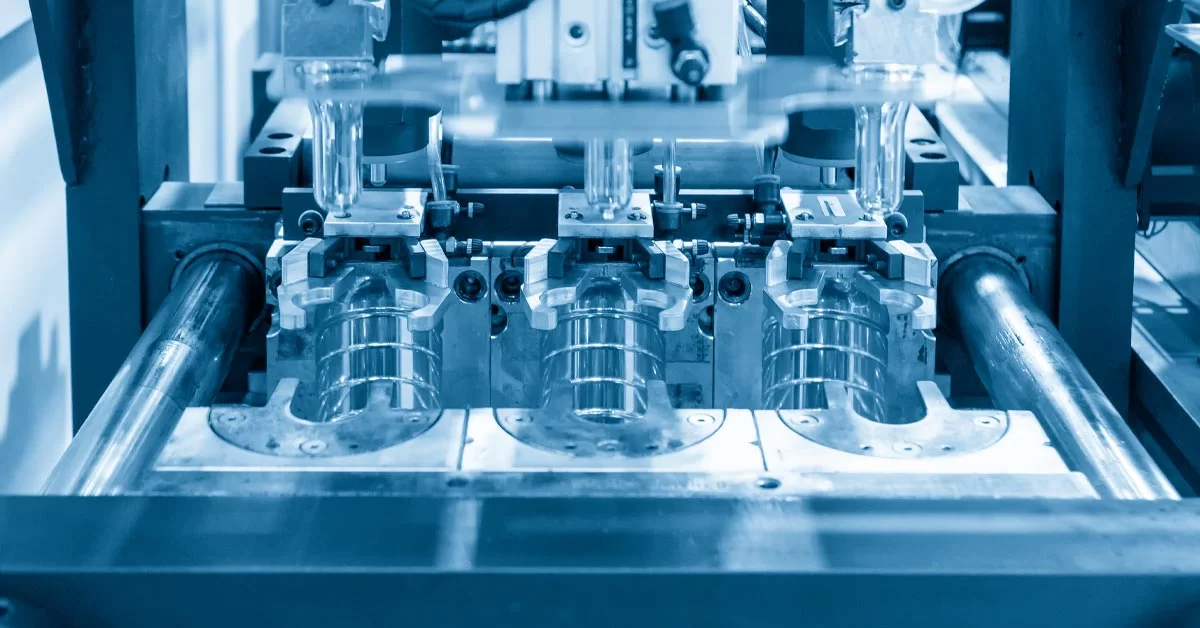

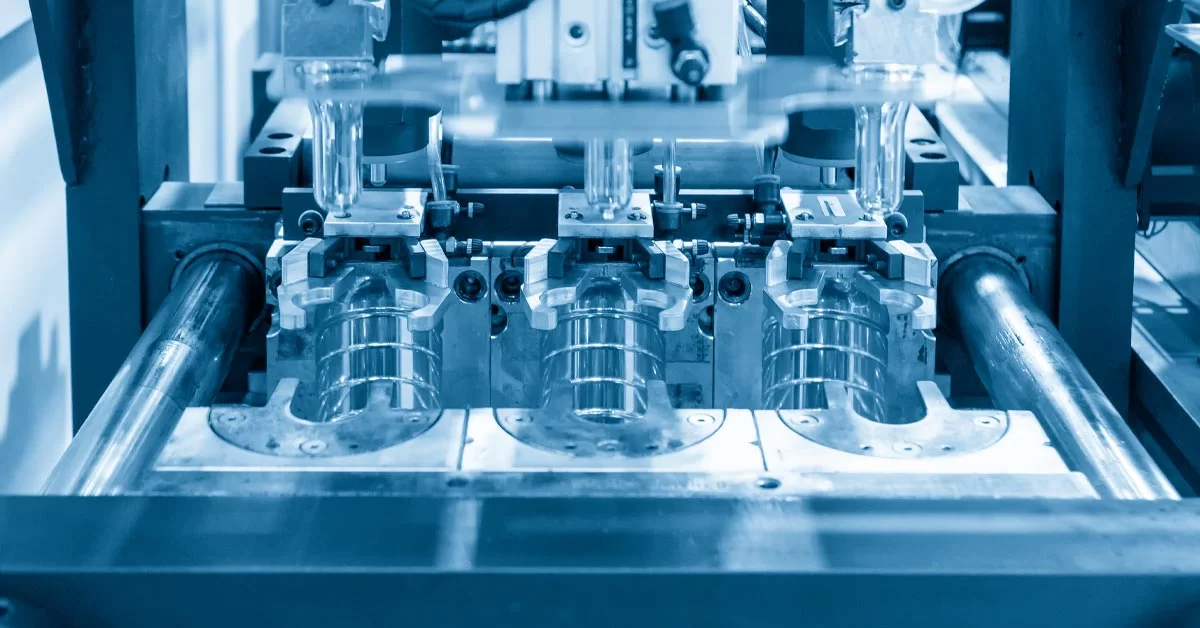

Plastic Mold Manufacturing

ALYA provides tailored solutions for various industries through its plastic mold manufacturing services. With our modern manufacturing infrastructure and expert team, we design and produce molds that meet the desired dimensions, shapes, and functional requirements of each project.

Plastic mold production forms the foundation of mass production projects. A well-designed and precisely manufactured mold directly impacts product quality, dimensional accuracy, and production efficiency. At ALYA, we carefully analyze each client’s requirements and plan the production process to meet those expectations.

Our molds are used across a wide range of sectors, including automotive, electronics, household appliances, packaging, and construction materials, and are produced to deliver long-lasting durability and high performance. Throughout the manufacturing process, we maintain strict quality standards, conducting the necessary checks at every stage and finalizing delivery with client approval.

Clients can easily share their project details, technical drawings, or design files with us via the quotation form on our website. This allows us to accelerate the preliminary assessment process and create the most accurate production plan.

Focusing on quality, reliability, and customer satisfaction, ALYA is a trusted name in plastic mold production, building long-term partnerships with its clients.